Our Equipment

Behind each and every one of our equipment specialists are years of industry experience and continuous training. Having the right skills is only half the story. To get the job done efficiently and accurately, we use breakthrough spray foam equipment. Our spray foam rigs are customized to tackle any spray foam application project, from 14-16’ box truck diesel power spray rig to a a gas powered 16’ V-nose foam Rig trailer.

SFCO Qatar Foam Insulation

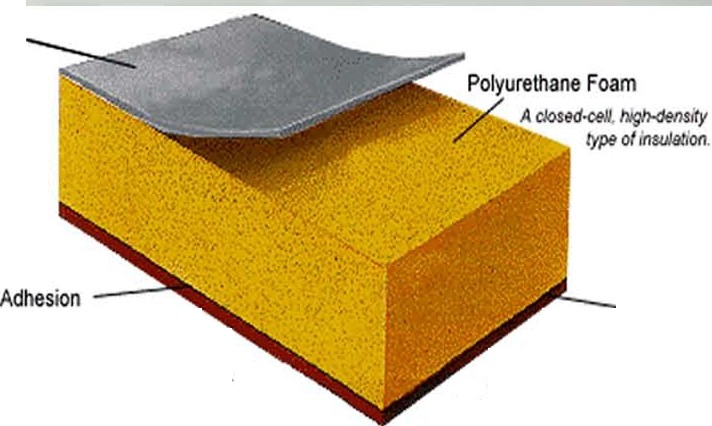

Foam-LOK is spray foam insulation and roofing systems. Foam-LOK locks in energy savings by adding an exceptionally high R-value insulation system to the building envelope and the roof deck. This advanced insulation and roofing system is spray applied to any shape and substrate. It seals the building envelope to stop heat transfer through the roof deck, minimizes conditioned air from escaping, and restricts unconditioned air from entering the building.

FOAM-LOK ROOFING

Sustainable Roofing Systems

Are you looking for a sustainable roofing system for commercial and industrial applications that doesn’t leak, reduces life cycle costs, and contributes to overall building energy savings?With construction expenses increasing and greater awareness of the long-term affects of energy use, building owners and design professionals are looking for cost-effective alternatives to conventional roofs. Foam-LOK™ is the alternative; a system that provides builders, architects, and owners with roofing solutions that support energy conservation, eliminates leaks and builds confidence.

Insulation

Heat loss or gain can occur through a building envelope by three primary mechanisms: conduction, convection and radiation. Three secondary mechanisms that influence the performance of insulation are air filtration, air intrusion and moisture accumulation. Spray polyurethane foam effectively controls the three primary and the three secondary mechanisms of heat transfer, resulting in insulation efficiencies well beyond that suggested by its high R-value alone.

Conduction

R-Value is well-publicized “status” to reflect insulation value to consumers. R-Value only measures conduction or the material’s ability to resist heat loss or gain. It is derived by taking the “k” value, determined by using an ASTM test method, and dividing it into the number one. The “k” value test is the actual measurement of heat transferred through a specific material. The test favors fiber insulation materials-fiberglass, rock wool, and cellulose fiber as the test does not account for air movement (wind), or moisture (water vapor). Zero wind and zero moisture are not real-world conditions.